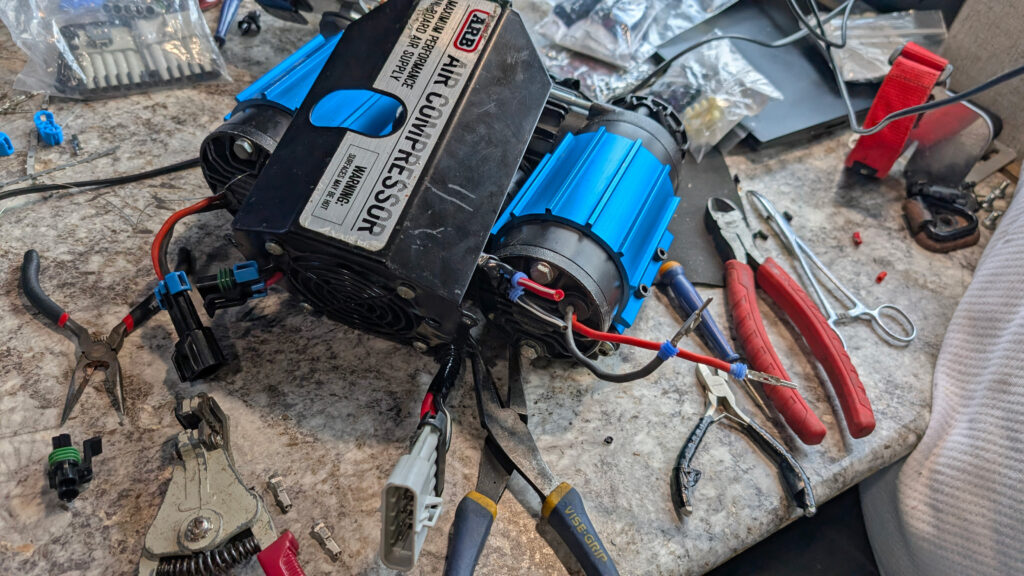

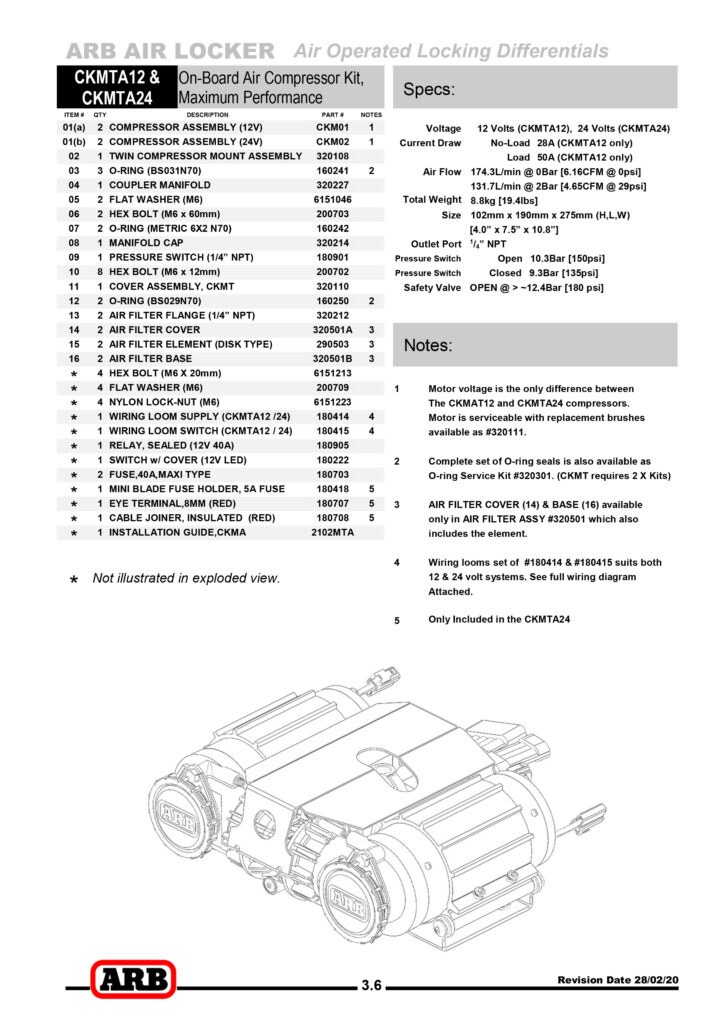

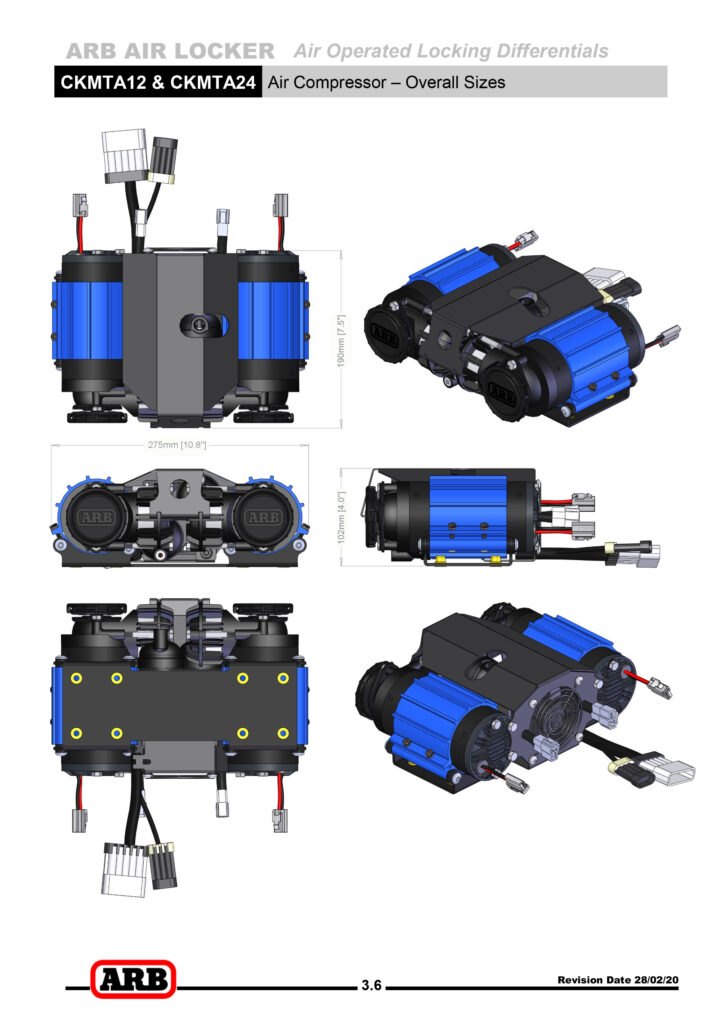

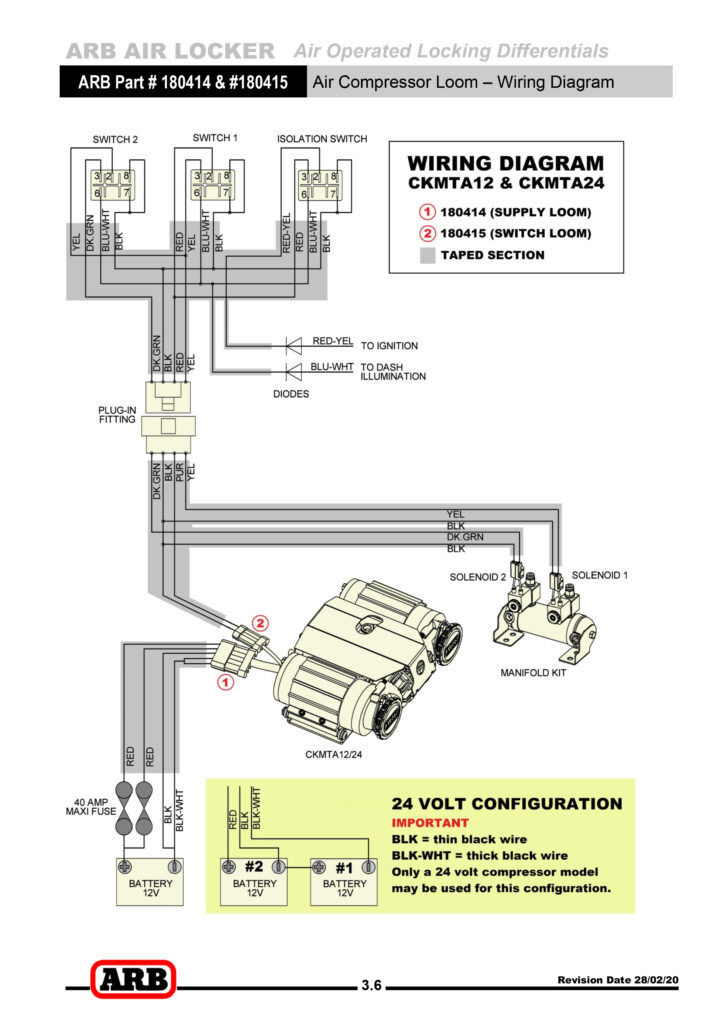

Even in Moab, after a full day of off-roading, I got tired of hunting down a reliable air compressor just to fill up the tires. That’s why I picked up this ARB CKMTA12 high-output twin air compressor second-hand off Facebook Marketplace. I thought it was new in box, but it turned out to have some hidden wear and electrical gremlins from prior use. For those unfamiliar, the CKMTA12 is one of ARB’s flagship 12V onboard compressors, with a twin motor, dual cylinder design that pumps out serious volume: up to 6.16 CFM (174 L/min) at 0 psi, dropping to around 4.68 CFM at 29 psi—making it one of the highest-flowing 12V compressors in its class, ideal for quickly airing up larger tires (like 35–40″) or running air tools. It draws up to 68.6 amps at max load (with no-load around 28–30A and typical under-load around 50A), so proper heavy-gauge wiring and twin 40A fuses are essential to avoid issues. It boasts a 100% duty cycle at moderate ambient temps (like 72°F/22°C, often listed as 60 minutes on/0 off for continuous run capability), max pressure of 150 psi, IP55 dust/moisture resistance, and weighs about 17.4 lbs in a compact 10.8″ x 7.5″ x 4″ footprint. It’s built tough for overlanding, but that dual-motor power means twice the potential for internal wear on a used unit—and in my case, that’s exactly what I found.

The main headaches were popping fuses and two separate plastic connectors burning out a pin connection. I went through a couple of replacement Delphi 280 connectors temporarily fixing issue with the wiring harness side:

- First one: https://www.amazon.com/dp/B0BMZHSVZW

- Second one: https://www.amazon.com/dp/B0D44QXBY8

These are weather-resistant Delphi-style 2-pin or multi-pin automotive connectors commonly used for upgrades or repairs on 12V systems like this. They are solid matches, but the issues kept recurring until I dug deeper.

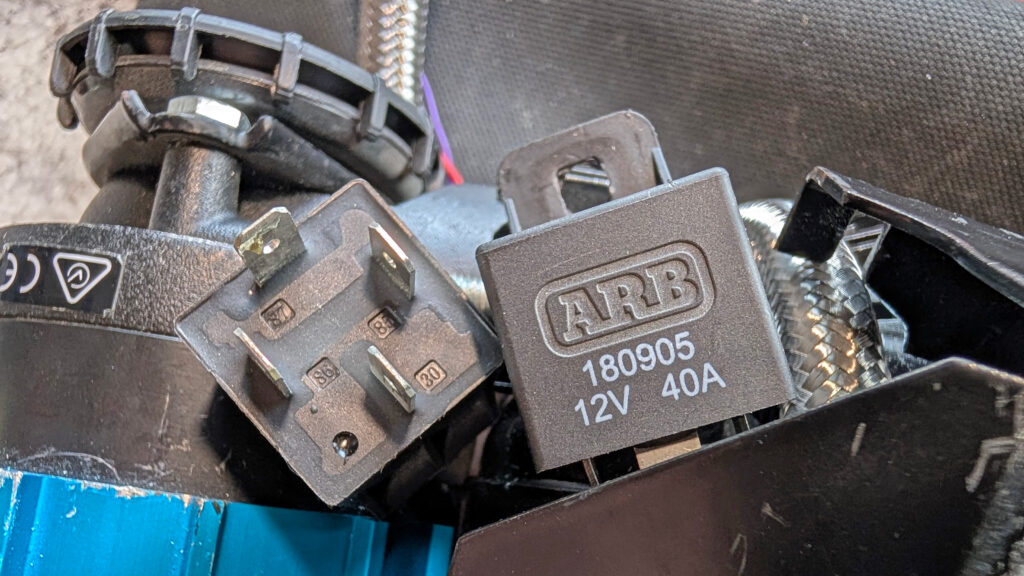

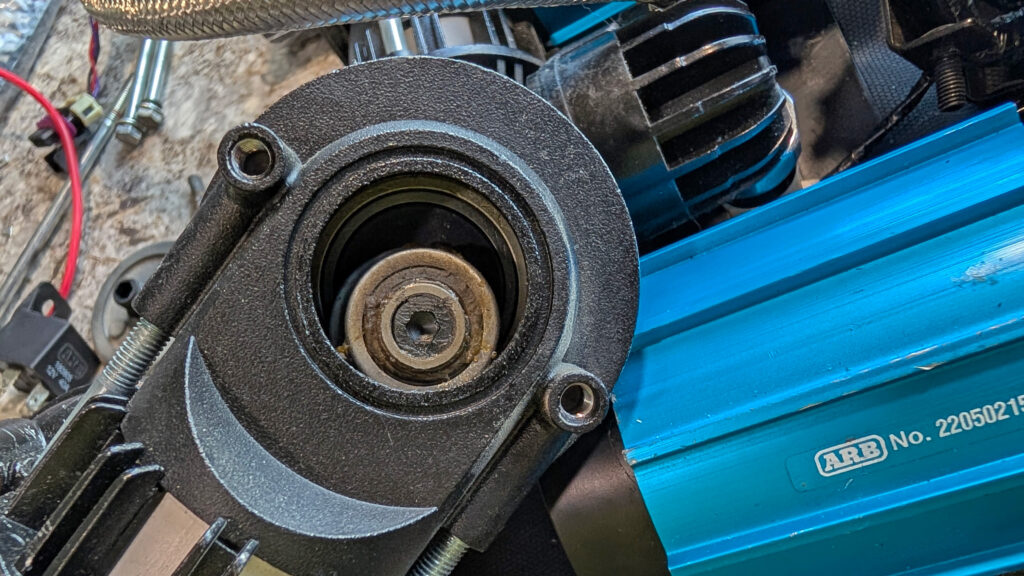

After swapping relays (no luck), multimeter-testing the 1/4” NPT pressure switch (which checked out okay), I finally opened up the motors and found the culprit: a straight, solid copper wire about 3/4 inch long had desoldered itself inside both motors. Vibration, heat cycling from heavy use, and age on this second-hand unit likely caused the solder joints to fail over time, leading to arcing, intermittent poor connections, overheating, and the burned pins/fuse pops I was chasing.

I carefully resoldered the wires in both motors using high-temp solder and flux for clean, strong joints, reassembled everything, double-checked continuity and resistance with the multimeter, and fired it up. Now it’s running strong—no more fuse pops, cutouts, or overheating. Lesson learned: even “new in box” used gear can have sneaky internal failures, especially on twin-motor units where both sides see the same abuse.

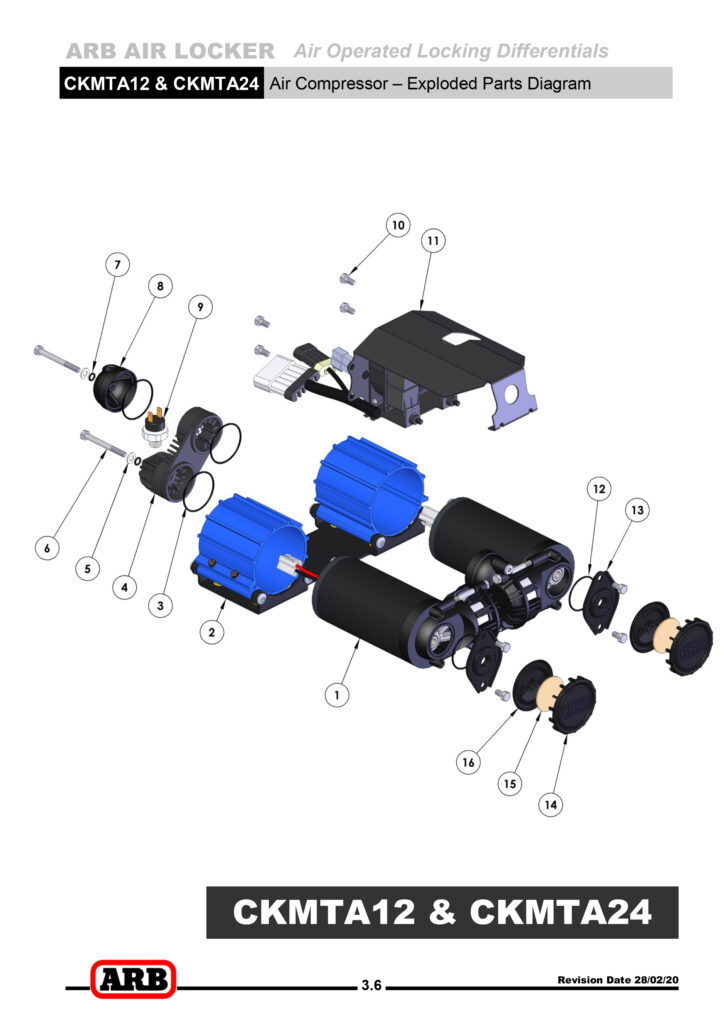

For reference, here’s the official ARB CKMTA12 manual PDF attached (wiring diagrams and exploded views were clutch for disassembly).

Video of the Repair

Short YouTube clip walking through the motor teardown on both sides, spotting the loose desoldered wires, and the resolder fixes:

Photos of the disassembled motors (both showing the desoldered copper wires) and the burned Delphi connector:

Integrating the ARB 1-Gallon Aluminum Air Tank

To make tire airing even faster and more convenient, I paired the repaired compressor with this ARB 1-gallon aluminum air tank (https://www.amazon.com/dp/B0BMQQ3V9Y, also ARB part #171507).

Key specs from ARB:

- 1-gallon capacity for high-volume air storage.

- Forged aluminum end caps TIG-welded to an extruded aluminum body—50% lighter than a comparable steel tank.

- Rated to a max working pressure of 150 psi.

- Four ¼-inch NPT ports (user-configurable), includes 2x JIC-4 male fittings.

- Horizontal or vertical mountable with minimal fluid retention (outlets at the lowest point).

- Daisy-chain compatible if you want to add more tanks later.

- Perfect for rapid tire inflation after trails or running air tools.

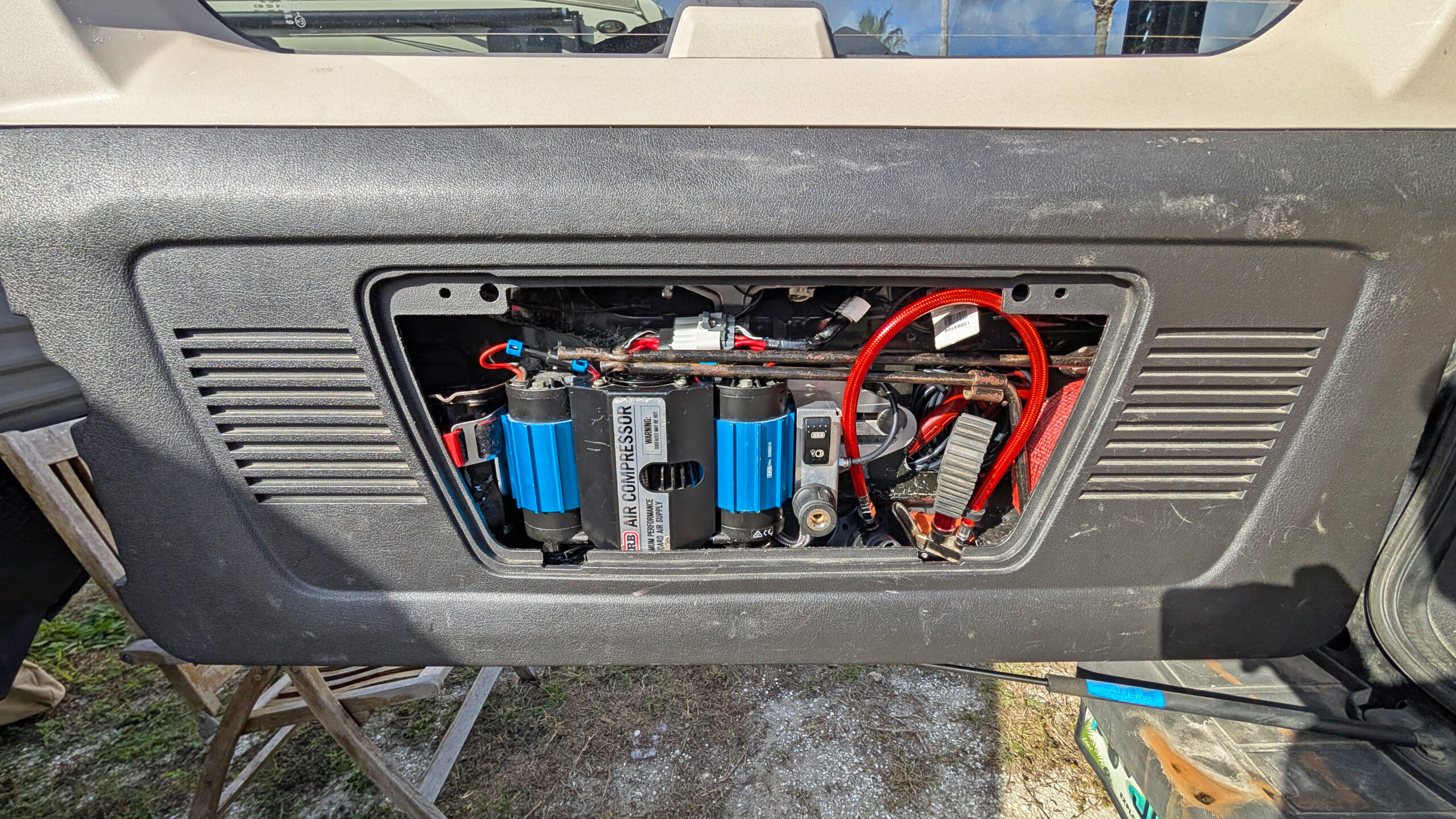

It’s a great match for the CKMTA12, giving you instant air reserve so the compressor doesn’t have to run constantly (or as hard). I mounted it in my prototype 2nd-gen all-aluminum tire carrier setup.

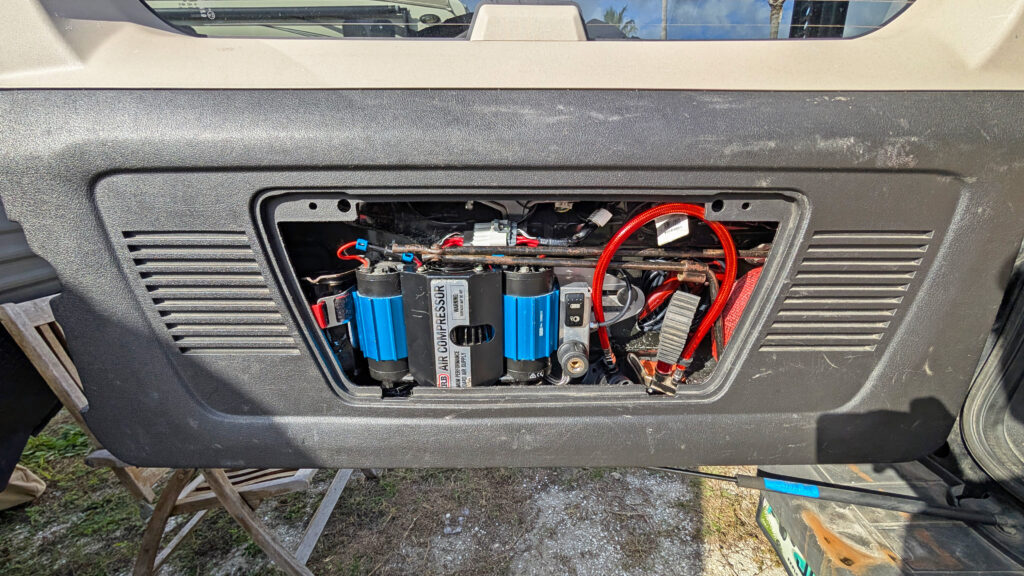

Prototype Mods

A week after the fix, I prototyped:

- The compressor on the hidden ARB Air Compressor Mount (tucked away, protected, easy access).

- The 2nd-gen all-aluminum modular tire carrier incorporating the 1-gallon ARB air tank.

Photos of the tire carrier prototype and air tank integration:

Quick Tips for ARB CKMTA12 Owners

- On used twin units, inspect both motor internals early—desoldered wires or corrosion can mimic external connector/relay failures and cause uneven performance.

- Use quality Delphi 280 replacements, but verify pinouts, secure soldering, and check for heat damage.

- Fuse properly (ARB specs support up to ~70A max draw, but start with 40–50A and monitor).

- Add an air tank like this one for faster, quieter inflation—huge upgrade for Moab-style trips where you want quick top-offs without constant compressor runtime.

If you’ve battled similar electrical issues (especially internal motor wiring) on your ARB twin setup or have questions about the tank/mount prototypes, hit the comments.

More H3 & H3T Hummer DIY coming soon—maybe some fog / head light tweaks next.

Leave a Reply