We’re thrilled to announce that our second-generation H3 Hummer Rock Sliders are nearing production. Building upon the success of our original design, we’ve focused on addressing key issues and introducing significant improvements.

Key enhancements include:

- Reduced shipping costs: We’ve implemented optimized packaging and shipping methods to minimize costs for our customers.

- Modular design: Our new design allows for easy customization and the integration of future features, even accommodating specific customer requests.

- Enhanced durability: We’ve taken steps to eliminate rust issues, ensuring long-lasting performance and reliability.

- Cost-effective solution: Without compromising on quality or durability, we’ve worked to make our rock sliders more affordable for our customers.

We’re confident that these advancements will exceed your expectations and provide you with a superior product. Stay tuned for updates on the official launch date.

As you know, the rising costs of fuel, steel, and shipping have made it increasingly challenging to maintain affordable prices for automotive accessories. In response to these challenges, we have developed a new generation of rock slider protection that offers significant cost savings and improved functionality.

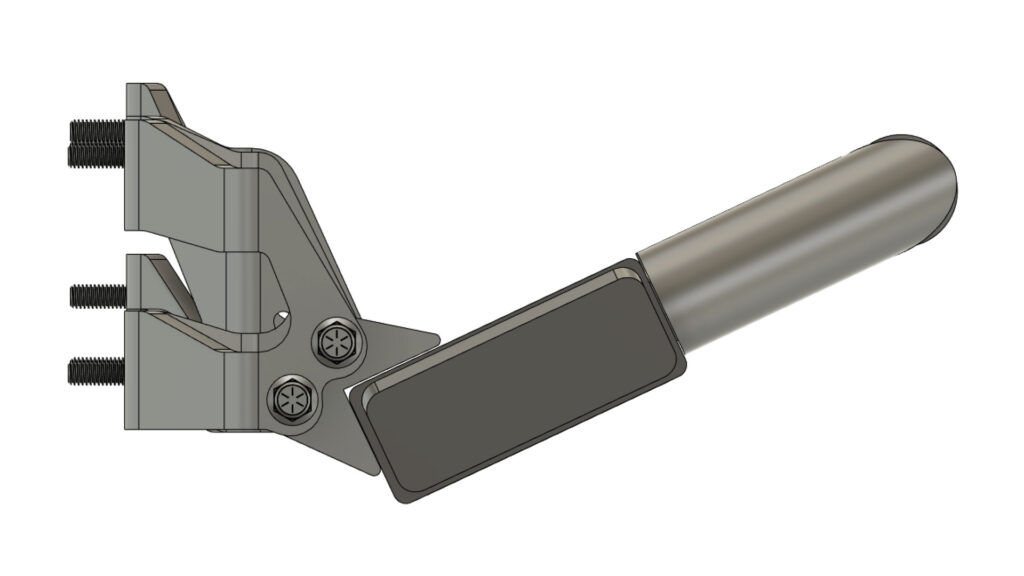

By combining the two rock sliders into a single shipment, we can significantly reduce shipping costs. However, traditional steel rock sliders are quite heavy, making them impractical for standard shipping methods. To address this issue, we have designed our new rock sliders using lightweight aluminum. This not only reduces the overall weight but also allows for a more compact shipping configuration.

Our modular design further enhances efficiency by enabling us to ship both rock sliders in a smaller package. This reduces shipping costs and minimizes environmental impact. We believe that our new aluminum rock sliders offer a superior solution for those seeking durable, affordable, and eco-friendly protection for their vehicles.

Isn’t Aluminum weaker than steel?

Aluminum is generally lighter and more malleable than steel, but it can also be stronger depending on the specific alloy and its composition. While steel is often considered stronger in terms of tensile strength, aluminum alloys can be engineered to have comparable or even superior properties in certain applications. Our application incorporates 5052 aluminum.

My goal is to create off-road parts that are so robust, they redefine expectations. Every component should be a testament to excessive design, built to withstand the harshest conditions. If a part fails, it’s a failure of the vehicle, not the component. To ensure unwavering strength, I’ve doubled the thickness of aluminum parts. My commitment is absolute: my parts will never be questioned.

Modularity is a cornerstone of my latest designs. The upcoming Modular Tire Carrier, slated for release before spring 2023, is a prime example. To further demonstrate this commitment, the 2nd Gen rock sliders feature a modular design with several advantages. First, the modularity reduces shipping costs by allowing separate shipment of the heavy 3/8-inch steel frame rail brackets and a bag of bolts in a USPS Flat Rate Box. This enables the rock sliders to be shipped together in the smallest possible package. Second, this modular approach will finally allow me to offer rock sliders for H3T Trucks. Lastly, it provides the flexibility to offer various designs without incurring significant overhead costs or reinventing the wheel each time.

While steel rock sliders can be effective for off-road use, they are prone to rust, especially if exposed to harsh conditions. My personal experience with steel rock sliders has reinforced this. Over the past decade, I’ve had to have my original sliders re-powder-coated multiple times due to extensive rust. To avoid ongoing maintenance and the associated costs, I’ve transitioned to using aluminum for my rock sliders. This material offers superior corrosion resistance and durability, making it a more practical choice for off-road enthusiasts.

I’m excited to refine my design by leveraging advanced CAD software, optimizing production costs and delivery methods, and reducing vehicle weight for improved performance and fuel efficiency. My goal is not just to enhance fuel economy but to explore the full potential of my design. Future modifications, such as rock lights and further cost reduction, will further elevate this project.

Leave a Reply